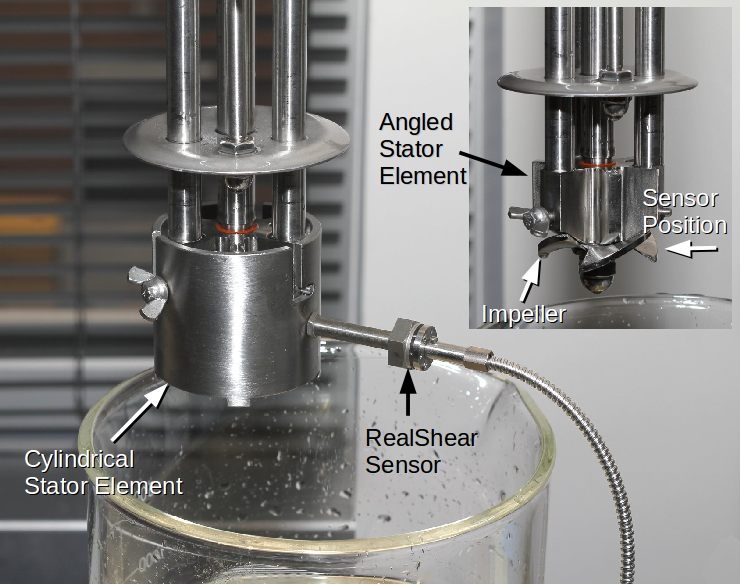

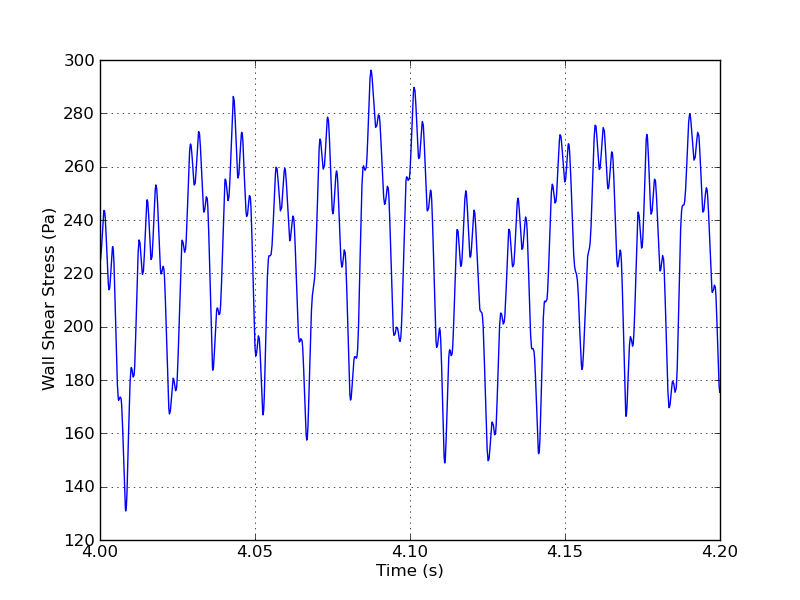

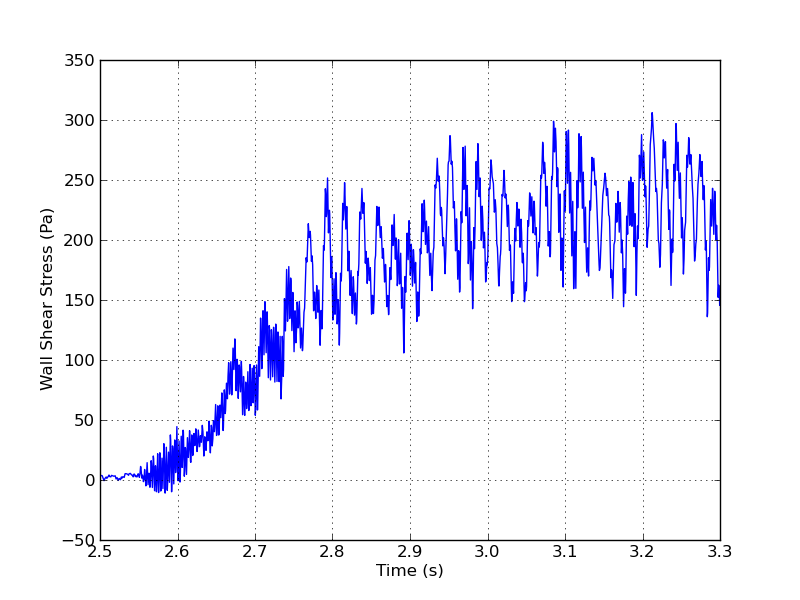

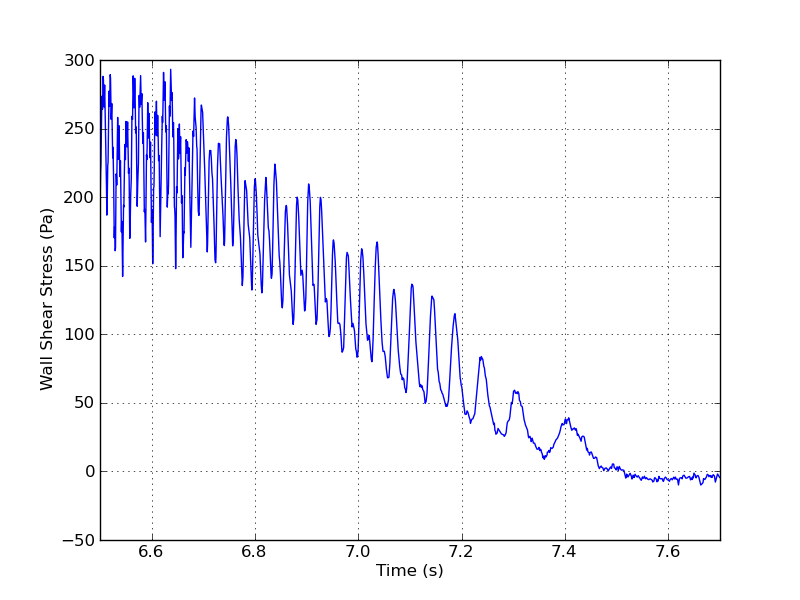

Tests were carried out with RealShear™ F-400 and F-8K shear stress sensors to measure the shear stress at the inner wall of the stator in a CJ-4E Arde Barinco reversible homogenizing mixer. This kind of mixer can be set for either downward flow or upward flow into a baffle plate. The sensor was attached to the stator with a custom 1/4”-80 threaded hole (see photos) such that the sensor face was flush with the inner wall of the stator with a small gap separating it from the blades of the impeller. Presented are plots of the time-dependent shear stress signal (in glycerol) showing the ability of the sensor to resolve individual passes of the impeller blades. Data such as this can be used to ensure proper processing or evaluate new mixer designs.

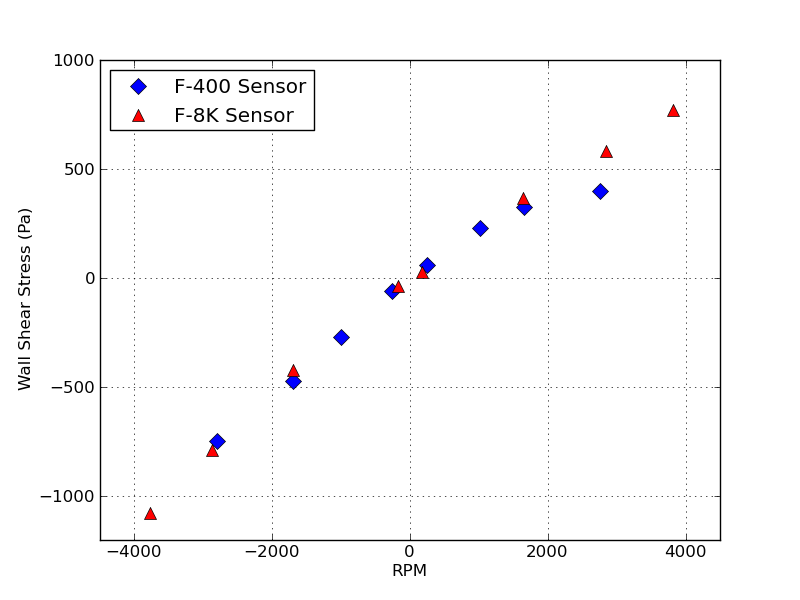

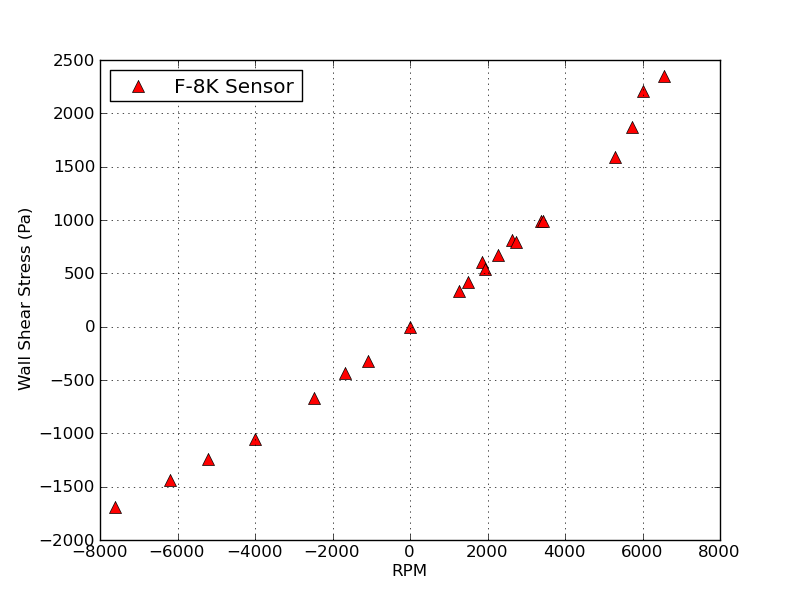

Below are plots of the dependence of shear stress on the rotational rate of the impeller for both glycerol (Newtonian) and shampoo (shear-thinning).