Lenterra Mini Mixer

April 7, 2023 2023-04-07 12:41Lenterra Mini Mixer

Lenterra Mini Mixer

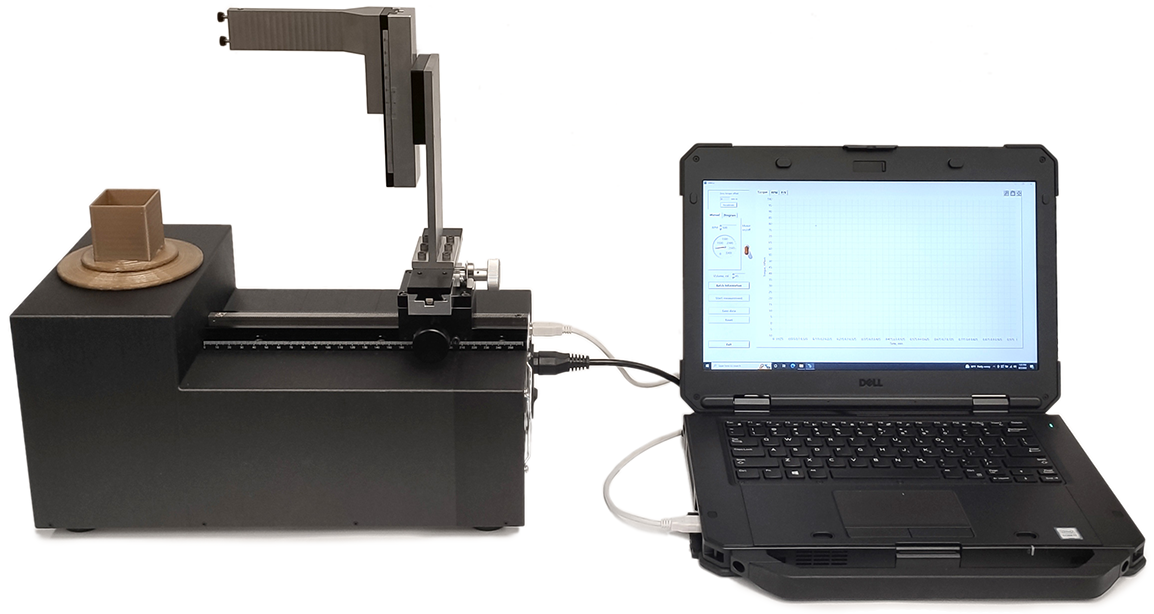

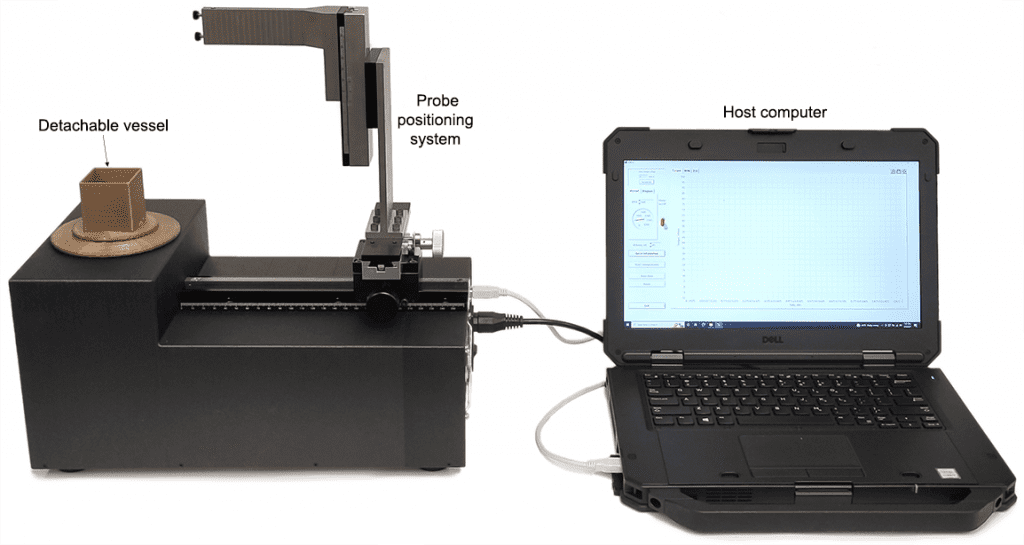

Lenterra Mini Mixer (LMM) is a bottom driven low volume mixer intended for use primarily as a mixer in the Lenterra Shear Device.

It can also be used as an autonomous mixer for low volume liquid and powder materials.

LMM is controlled by a host computer that allows for programming of mixing cycles, varying RPM, and displaying values of rotational torque and RPM in real time. Detachable vessels are available in various volumes and shapes, and allow for quick allow for quick replacement of the agitator. The mixer includes a positioning system for precise insertion of a test probe into desired position within the vessel. When LMM is a component of Lenterra Shear Device, a Drag Force Flow (DFF) sensor is used as such a test probe. Accessories include replaceable vessel/agitator assemblies.

Lenterra Shear Device measures instantaneous shear stress and shear rate and its distribution over the mixer volume

as well as real-time torque and RPM in a mini-vessel that can be a scaled down actual processing vessel. Flow force and

shear stress measured five hundred times per second which allows for observation of detailed dynamics of the flow

(such as the effect of each mixer blade separately) and for statistical analysis. Using a small volume of material and

QbD approach, it can determine:

- Excipient variability

- Formulation variability

- Processing end point

- Critical Material Attributes (CMAs) and Critical Process Parameters (CPPs)

LMM specifications

| Length, cm | 39 |

|---|---|

| Width, cm | 21 |

| Height, cm | 47.5 |

| Weight, kg | 14.2 |

| RPM | 10 - 3000 |

| Torque measurement range, mN·m | 0 - 100 |

| Power | 88 ~ 132 VAC, 60 Hz |

Host computer and software

A rugged laptop is used as host computer for LMM. The device is controlled either by LENFLOW-LMM Lenterra Shear Device software or an autonomous LMM software preloaded to the laptop.

Accessories: Vessel/agitator assembly

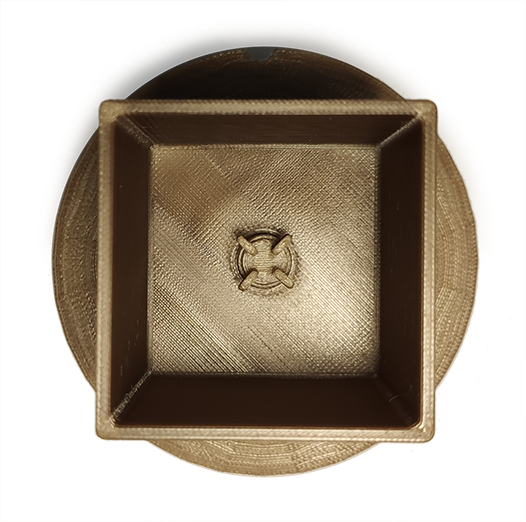

Square vessels

| Assembly 1 | Assembly 2 | |

|---|---|---|

| Vessel hight, mm | 47 | 47 |

| Height, cm Vessel width, mm | 45 | 45 |

| Agitator diameter, mm | 25.4 | 12.7 |

| Wall thickness, mm | 2.5 | 2.5 |

| Material | PEEK | PEEK |

Round vessels

| Vessel hight, mm | 66 |

|---|---|

| Vessel diameter, mm | 45 |

| Agitator diameter, mm | 16.9 |

| Wall thickness, mm | 2.5 |

| Material | CF PEEK |