Mixing and Blending

October 18, 2021 2021-12-05 9:45Mixing and Blending

Mixing and Blending

Offline measurements provide limited opportunity to closely track the process towards completion and rapidly detect any mechanical failure of the equipment. As a result, executing the process using offline measurements is likely to carry the unintended costs of wasted energy, compromised throughput and product quality. Inline technology that instantaneously detects the endpoint of a mixing process eliminates these issues, resulting in considerable economic return.

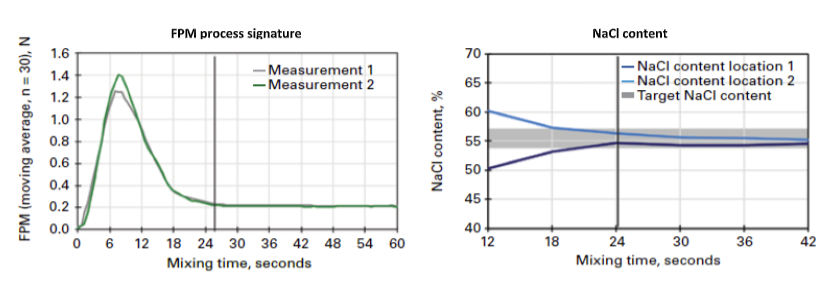

LIR technology is well suited to monitoring the mixing, blending or granulation processes, due to its capability of real-time measurements inline. The Force Pulse Magnitude (FPM) and Powder Consistency Factor (PCF) metrics recorded over the processing period provide unique process signatures, and, combined, the process fingerprint. The following examples of process monitoring illustrate the concept.

Detecting the point of homogeneity after liquid addition in a vertica twin-shaft mixer

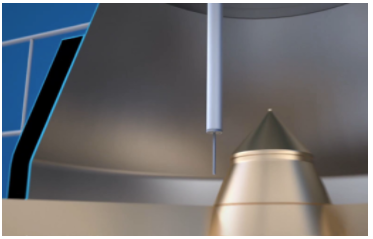

A LIR-D configuration was used to monitor dispersion of a liquid component in a powdered food product being mixed in a vertical twin-shaft, with a DFF sensor installed into the mixer volume as shown in the picture.

While changes in the physical properties of the mixture were monitored in real time using the LIR,, samples were instructed at two location for off-line analysis. The liquid contained sodiul chloride (NaCl), so its distribution through the powder could be measured offline by potentiometric titration.