Lenterra Home Page

December 22, 2020 2025-06-25 18:13Lenterra Home Page

Revolutionary step in rheometry

Hello, I'm Ronald Dumple!

One-on-One Financial Coaching

I can help you find them through one-on-one financial coaching.

Revolutionary step in rheometry

Featured products

One solution for your many needs

LIR characterizes powders, liquids or any other material that flows or can flow

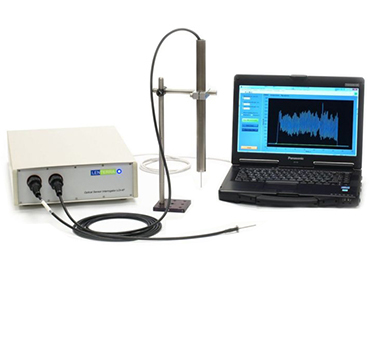

Micro-optical flow force measurement technology

Lenterra’s measurement technology relies on extreme sensitivity of optical resonators to provide a miniature and sensitive but robust and simple flow sensor with no moving parts.

News

Join us at the 66th Battery Symposium on booth 4

Join us at the 66th Battery Symposium on booth 4 October 2025 We are pleased to announce that our representative in Japan, Takashi Nishimura (Reifycs

Lenterra has developed a methodology for water content optimization in HSWG using its inline rheometer

Lenterra has developed a methodology for water content optimization in HSWG using its inline rheometer July 2025 The company has completed a study

Lenterra will be presenting on the International Granulation Workshop in Hamburg, Germany

Lenterra will be presenting on the International Granulation Workshop in Hamburg, Germany June 2025 We will deliver an oral presentation

Lenterra Inline Rheometer (LIR) Predicted Tablet Properties in a Study by University of Birmingham and GSK Ware

Lenterra Inline Rheometer (LIR) Predicted Tablet Properties in a Study by University of Birmingham and GSK Ware August 2024 A study published

Indian Pharmaceutical Alliance Recommends Lenterra’s Drag Flow Force (DFF) Technology as a Sensitive PAT Tool for High-Shear Granulation

Indian Pharmaceutical Alliance Recommends Lenterra’s Drag Flow Force (DFF) Technology as a Sensitive PAT Tool for High-Shear Granulation July 2024

Lenterra’s Technology Featured on PAT & QbD Conference in India

Lenterra’s Technology Featured on PAT & QbD Conference in India May 2022 Dr. Sanjay Sharma, VP & Head-Technology Transfer of Lupin Ltd.,

Recognition

Ajit Narang, Ph.D.

VP, Chemistry Manufacturing and Controls, ORIC Pharmaceutical

Dr. Sanjay Sharma, VP & Head-Technology Transfer of Lupin Ltd. Lenterra’s LIR technology was featured by Dr. Sharma at “PAT & QbD”

Ajit Narang, Ph.D.

VP, Chemistry Manufacturing and Controls, ORIC Pharmaceutical

In comparison with off-line rheometer, Lenterra Inline Rheometer demonstrated superior sensitivity to changes in the wet mass during granulation

Journal of Pharmaceutical Sciences, 2014

DFF sensor can be used as a tool to identify the end point of a WG process with respect to granule densification or wet mass consistency, and as a

Journal of Pharmaceutical Sciences, 2016

Studies indicate that DFF sensor can be a valuable tool for wet granulation formulation and process development and scale-up, as well as for routine

Pharmaceutical Processing World, 2017

The data presented here demonstrate that in-line DFF measurements can be used to monitor the variation in granule properties during a HSWG process.

Powder and Bulk Engineering 2020

DFF sensors are robust instruments capable of detecting small differences in the properties of process materials with a high degree of sensitivity.