Material Characterization

November 22, 2021 2025-09-18 17:54Material Characterization

Material Characterization

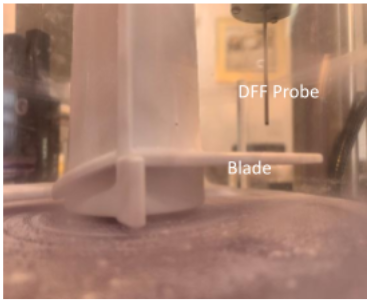

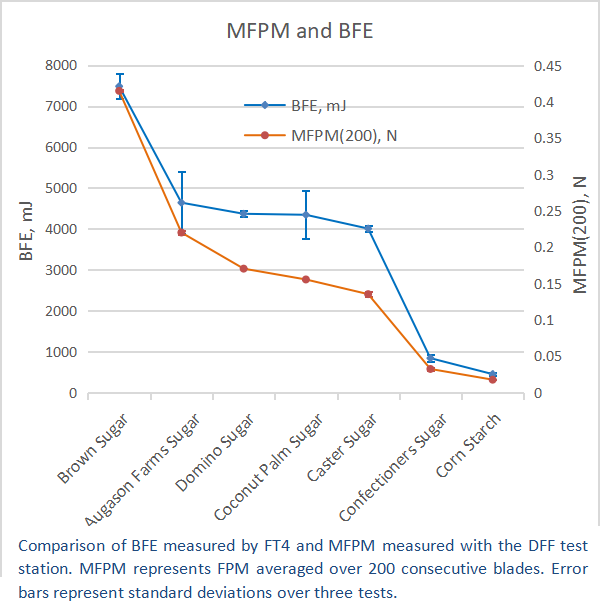

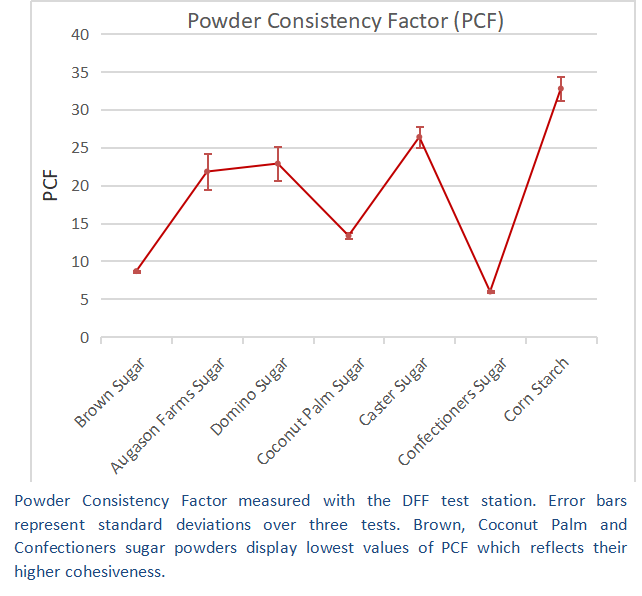

Various materials can be tested using a DFF sensor installed in a small mixer, with a probe permanently installed in a specific position, typically just above the blade, as seen in the figure. After a particular amount of powder is added to the mixer, flow force measurements are conducted at a rate of 500 per second. The mixer speed, the volumetric amount of powder, and the probe position are kept unchanged for a standard test. The material is characterized with two principal metrics of LIR technology: the mean force pulse magnitude (MFPM) that is the measure of flow force, and the Powder Consistency Factor (PCF) that characterizes the uniformity or cohesiveness of the powder (please refer to White Paper 13 for definition of MFPM and PCF). The two metrics and their uncertainties are obtained by averaging their values over the pre-selected measurement time, which is typically 10 to 30 seconds (see also White Paper 15).

Comparing material characterization of dry powders using an off-line LIR and FT-4 Powder Rheometer®

Characterization of grain samples

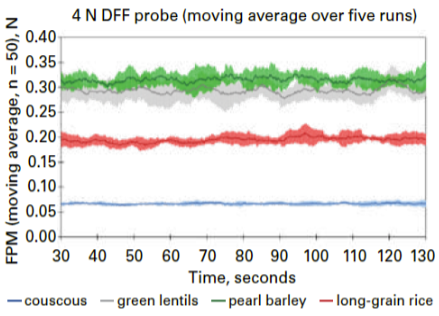

Force Pulse Magnitude (FPM), an output of the LIR measurement (see White Paper 3 for the description of the metric), is an effective characteristic that reliably differentiates powders with different masses/sizes of the particles. For example, in a mixing study with four grain samples, where each samples was mixed in a laboratory mixer for 120 seconds, the real time FPM data demonstrate highly repeatable levels which are clearly different between the four grains.

Measuring blends of small and large particles

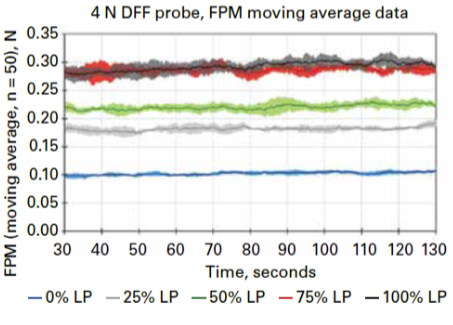

In another example, two grain samples with small particles (SP) and large particles (LP), respectively, were blended as binary mixtures and tested in a similar conditions. Again, these trials produced highly repeatable data and evidence of blend uniformity, as seen on the plot. There also a positive non-linear trend between the percentage of large particles and the magnitude of the FPM signal.

Please see details of these studies in a publication of Powder and Bulk Engineering.